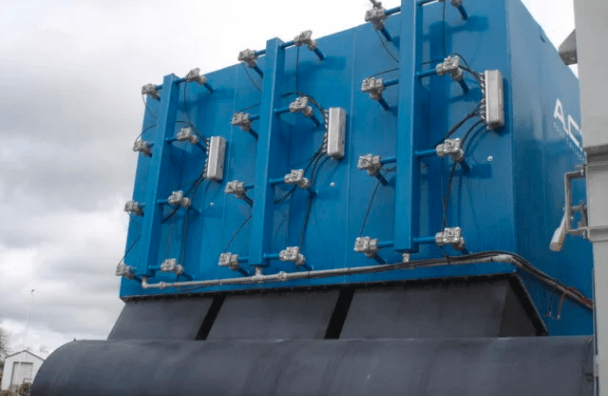

With millions of CFM going through operating A.C.T. Dust Collectors every day worldwide, we have experience with applications in many industries! Custom designed and built systems are common, and our engineering team can help find the dust collection system that's right for you.

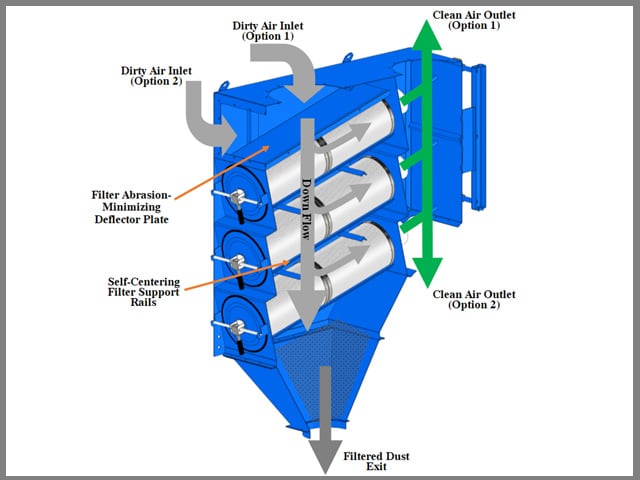

Dirty air from the dust source enters the A.C.T. dust collector at the top of the main housing. There are inlets on the roof and optional inlets on the front for the most efficient connection. As air enters the dust collector, dust accumulates on the outside of the filters as air is drawn through the high-efficiency media. The air flowing down through the system greatly assists the fallout of dust into the hopper where it is discharged. When the pulse clean system activates and accumulated dust is released from the cartridges, the air flowing downward through the collector assists dust fallout again. This avoids dust from getting re-entrained and accumulating on the filter again. Systems with vertical filters — with air entering from the side or below — struggle to avoid dust getting picked back up in the airstream or "re-entrained."

The ACT 4-32 is efficient and effective for many dust collection applications including metalworking, weld smoke and fumes, blasting, plastics and many more. Typically the ACT 4-32 would be found collecting dust and debris from a variety of areas around the building. This could include multiple weld cells or processes that require dust/fume collection.

The downward airflow technology of this horizontal cartridge style dust collector, maximizes the airflow in the collector to assist with dust separation. The 8,128 square feet of media in the ACT 4-32 will help to ensure the dust collection system is operating at optimum performance.

When this dust collection system was designed, maintenance was top of mind. Our cartridge dust collectors are easy to maintain because of the following standard features:

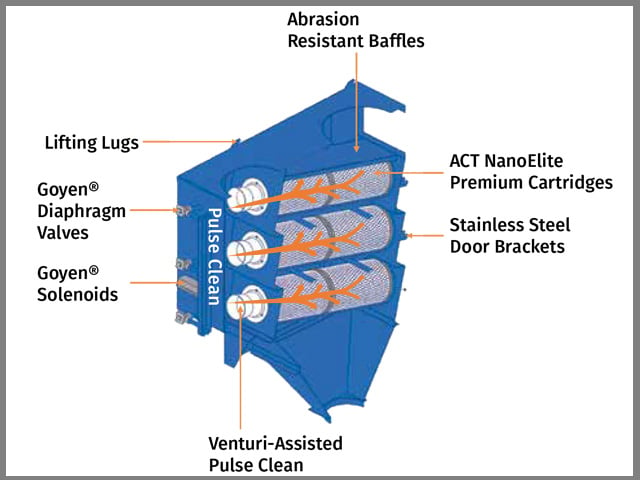

This ACT 4-32 dust collection system holds (32) cartridge filters and comes standard with our A.C.T. Nano-Elite Nanofiber Cartridges. Our cartridge dust collectors are built to have a low total cost of ownership. Because our dust collectors take standard filters, the cost of replacement filters is much lower than systems that come with custom sized or shaped filters. It is important to consider filter replacement cost at the time of purchase.

Dirty air from the dust source enters the A.C.T. dust collector at the top of the main housing. There are inlets on the roof and optional inlets on the front for the most efficient connection. As air enters the dust collector, dust accumulates on the outside of the filters as air is drawn through the high-efficiency media. The air flowing down through the system greatly assists the fallout of dust into the hopper where it is discharged. When the pulse clean system activates and accumulated dust is released from the cartridges, the air flowing downward through the collector assists dust fallout again. This avoids dust from getting re-entrained and accumulating on the filter again. Systems with vertical filters — with air entering from the side or below — struggle to avoid dust getting picked back up in the airstream or “re-entrained.”

Your A.C.T. dust collector comes standard with industry-best A.C.T Nano-Elite media. These feature a MERV 15 efficiency rating for effective collection of extremely fine dust, smoke and fume, removing 99.9% of particulate from the air. The cleaned air is then directed to the location of your choice: either returned to your facility or exhausted to the environment.

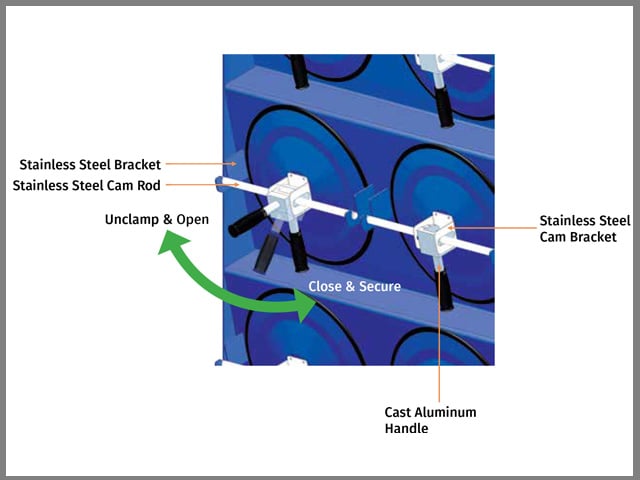

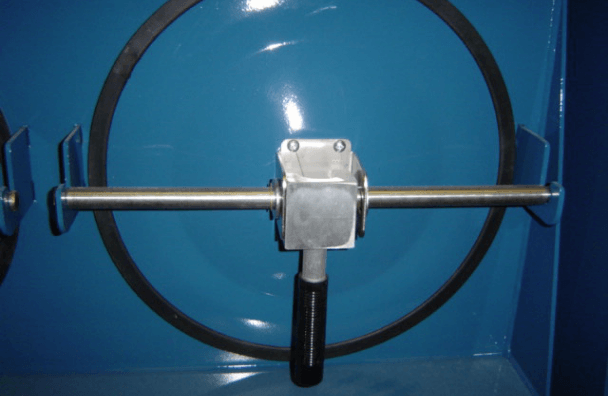

The patented door design of A.C.T. dust collectors is simple, fast and secure. The cast aluminum handle locks the door shut against the dust collector. The heavy-duty cross-rod and brackets on the dust collector and cam are all stainless steel. Knobs, hinges, springs, threads and wasted time are eliminated. Lift the handle and door comes off. Set the cross-rod in the brackets, lower the handle and it’s locked securely. Click Here to watch the video.

Inside the A.C.T. dust collector, the design continues to work. Two rails support the cartridge filters from the front to the back of the housing, eliminating the need for interior yoke support frame cantilevered from the collector tube sheet. The pulse clean system is unobstructed inside the filter for maximum effectiveness.

Get behind the system, and the working end of the A.C.T. dust collector is equipped for any requirement. Goyen diaphragm valves and electric solenoids are the industry standard. Coupled with Dwyer Instruments digital, solid-state pulse control, complete with on-board pressure switch, you can control on-line, on-demand and downtime cleaning. All this is enclosed in a weatherproof housing for reliable operation.

The main housing of your A.C.T. dust collector is 7 and 10 gauge, all-welded steel. Systems with bolted panel construction can leak over time, so the housing of the A.C.T dust collector is fabricated with continuous, welded seams. Behind every row of two filters is a venturi for maximum performance on the pulse cleaning.

With hundreds of A.C.T. dust collectors manufactured and installed, every serial number is a statement of quality. Lifting lugs are engineered to the correct lifting angle and formed doors for maximum rigidity, coupled with deep one-piece gaskets, maintain the seal. Angle iron support structure and base plates are pre-punched for easy installation. A fastener kit is included with Grade 5, zinc-plated fasteners. A premium blast, prime and paint process ensures the system will remain in excellent cosmetic condition for many years.

At A.C.T. Dust Collectors, we do more than sell dust collectors. We want to be your number one resource for all your dust collection needs. From our helpful glossary of terms to our on-demand webinars and videos – you can find it all right here. Manuals and brochures for all of our models of dust collectors are also accessible in downloadable formats.

With millions of CFM going through operating A.C.T. Dust Collectors every day worldwide, we have the solution to every application. Custom designed and built systems are common, and our engineering team can help find the dust collection system that's right for you.

| Collector Design | STD | OPT |

| Mild Steel Construction | ✔ | |

| Venturi-Assisted Pulse Filter Cleaning System | ✔ | |

| ACTion-Lock Quick Release Filter Doors | ✔ | |

| Inlets (2) Available | ✔ | |

| A.C.T. Nano-Elite Nanofiber Cartridges | ✔ | |

| Dust Drawer/Tray Bottom Material Outlet | ✔ | |

| Stainless Steel Construction | ✔ | |

| High Temperature Construction | ✔ | |

| Explosion Protected Models | ✔ | |

| Direct Drive Fans | ✔ | |

| Chamber and Exhaust Silencers | ✔ | |

| Air Management Modules | ✔ | |

| Steep-Sided Hopper | ✔ | |

| Multi-Module Hopper for Single Outlet | ✔ | |

| Service Platform (OSHA compliant) | ✔ | |

| Sprinkler Coupler | ✔ | |

| Alternate Filter Media Options | ✔ | |

| After Filter Housing | ✔ | |

| HSPA/ASHRAE Filters | ✔ | |

| Damper Pack | ✔ | |

| Bag-In/Bag-Out Kit (Filter & Discharge) | ✔ | |

| High Temp (MERV 13) Filter | ✔ | |

| HEPA/ASHRAE Afterfilters | ✔ |

| Paint System | STD | OPT |

| Primed and Painted Interior | ✔ | |

| Multi-Coat Paint Finish | ✔ | |

| Custom Color | ✔ | |

| Epoxy Coating | ✔ |

| Hopper Discharge | STD | OPT |

| Drum Cover and Hose | ✔ | |

| Slide Gates | ✔ | |

| Rotary Valves and Transitions | ✔ | |

| Screw Conveyors | ✔ |

| Electrical Controls, Gauges & Enclosures | STD | OPT |

| Control Box w/Digital Timer in NEMA 4 Enclosure | ✔ | |

| Control Panel with Magnetic Starter and Digital Timer Control | ✔ | |

| Control Panel with Variable Frequency Drive (VFD) and Digital Timer Control | ✔ | |

| Custom Panels | ✔ | |

| Solenoid Heater Kit | ✔ |

| Warranty | STD | OPT |

| 10-Year Warranty | ✔ |

With millions of CFM going through operating A.C.T. Dust Collectors every day worldwide, we have the solution to every application. Custom designed and built systems are common, and our engineering team can help find the dust collection system that's right for you.

| Model | Height | Width | Depth | # of Filters | Filter Area |

| ACT 2-2DD | 70 | 26 | 56 | 2 | 508 |

| ACT 2-2H | 118 | 50 | 56 | 2 | 508 |

| ACT 2-4 | 127 | 40 | 61 | 4 | 1,016 |

| ACT 2-8 | 127 | 40 | 87 | 8 | 2,032 |

| ACT 2-12 | 127 | 60 | 87 | 12 | 3,048 |

| ACT 2-24 | 127 | 120 | 87 | 24 | 6,096 |

| ACT 3-3DD | 95 | 26 | 56 | 3 | 762 |

| ACT 3-3H | 141 | 50 | 56 | 3 | 762 |

| ACT 3-6 | 146 | 40 | 61 | 6 | 1,524 |

| ACT 3-12 | 146 | 40 | 87 | 12 | 3,048 |

| ACT 3-18 | 146 | 60 | 87 | 18 | 4,572 |

| ACT 3-24 | 146 | 80 | 87 | 24 | 6,096 |

| ACT 3-36 | 146 | 120 | 87 | 36 | 9,144 |

| ACT 3-48 | 146 | 160 | 87 | 48 | 12,192 |

| ACT 3-54 | 146 | 180 | 87 | 54 | 13,716 |

| ACT 3-72 | 146 | 240 | 87 | 72 | 18,288 |

| ACT 4-16 | 164 | 40 | 87 | 16 | 4,064 |

| ACT 4-32 | 164 | 80 | 87 | 32 | 8,128 |

| ACT 4-48 | 164 | 120 | 87 | 48 | 12,192 |

| ACT 4-64 | 164 | 160 | 87 | 64 | 16,256 |

| ACT 4-80 | 164 | 200 | 87 | 80 | 20,320 |

| ACT 4-96 | 164 | 240 | 87 | 96 | 24,384 |

| ACT 4-112 | 164 | 280 | 87 | 112 | 28,448 |

| ACT 4-128 | 159 | 319 | 87 | 128 | 32,512 |

| ACT 4-144 | 164 | 360 | 87 | 144 | 36,576 |

| ACT 4-160 | 218 | 398 | 87 | 160 | 40640 |

| ACT 5-20 | 178 | 40 | 87 | 20 | 5,080 |

| ACT 5-40 | 178 | 80 | 87 | 40 | 10,160 |

| ACT 5-60 | 178 | 120 | 87 | 60 | 15,240 |

| ACT 5-80 | 178 | 160 | 87 | 80 | 20,320 |

| ACT 5-100 | 178 | 200 | 87 | 100 | 25,400 |

A.C.T. Nano-Elite high efficiency cartridge filters remove 99.9% of the particulate from the air stream. They carry a MERV 15 rating (best in the industry). The cleaned air is then directed to the location of your choice, either returned to the facility or exhausted to the environment.

Phone: 763-557-7162

Toll Free: 800-422-1316

Locations: