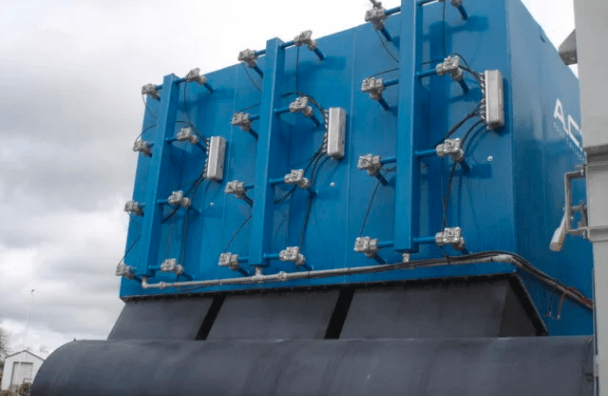

Industry demands fast, efficient and effective dust collection solutions. A.C.T. Dust Collectors introduces the ACTion Booth Power Module, one of the most versatile industrial dust collection systems for industrial air filtration.

The unique industrial dust collection system design combines heavy-duty construction with multifunction design in a plug-and-play package. Simply position the ACTion Booth Power Module at the back of your work area that produces dust. Dirty air is drawn into the oversized inlet, which has vertical louvers to evenly distribute incoming dirty air while providing velocity reduction for heavy material separation for longer filter life.

The ACTion Booth is a compact dust collector with a small footprint for applications including sanding, blasting and deburring, powder coating and many more. Typically, the ACTion Booth would be found collecting dust and debris for a smaller area in a facility.

ACTion Booth Power Module features an integral blower motor that is surrounded with noise attenuation material for quiet operation. Clean air is returned out the top of the industrial dust collector and recirculated back to your factory floor.

.jpg)

When this dust collection system was designed, maintenance was top of mind. Our cartridge dust collectors are easy to maintain because of the following standard features:

High-efficiency vertical cartridge filters capture the dust, while an automatic pulse clean system maintains the system during operation. Accumulated dust is contained in the two dust drawers at the base, easily removable for disposal as needed.

Get behind the system, and the working end of the A.C.T. dust collector is equipped for any requirement. Goyen diaphragm valves and electric solenoids are the industry standard. Coupled with Dwyer Instruments digital, solid-state pulse control, complete with on-board pressure switch, you can control on-line, on-demand and downtime cleaning. All this is enclosed in a weatherproof housing for reliable operation.

Your A.C.T. dust collector comes standard with industry-best A.C.T Nano-Elite media. These feature a MERV 15 efficiency rating for effective collection of extremely fine dust, smoke and fume, removing 99.9% of particulate from the air. The cleaned air is then directed to the location of your choice: either returned to your facility or exhausted to the environment.

With hundreds of A.C.T. dust collectors manufactured and installed, every serial number is a statement of quality. Lifting lugs are engineered to the correct lifting angle and formed doors for maximum rigidity, coupled with deep one-piece gaskets, maintain the seal. Angle iron support structure and base plates are pre-punched for easy installation. A fastener kit is included with Grade 5, zinc-plated fasteners. A premium blast, prime and paint process ensures the system will remain in excellent cosmetic condition for many years.

At A.C.T. Dust Collectors, we do more than sell dust collectors. We want to be your number one resource for all your dust collection needs. From our helpful glossary of terms to our on-demand webinars and videos – you can find it all right here. Manuals and brochures for all of our models of dust collectors are also accessible in downloadable formats.

With millions of CFM going through operating ACT Dust Collectors every day worldwide, we have the solution to every application. Custom designed and built systems are common, and our engineering team can help find the dust collection system that's right for you.

| Collector Design | STD | OPT |

| Mild Steel Construction | ✔ | |

| Venturi-Assisted Pulse Filter Cleaning System | ✔ | |

| A.C.T. Nano-Elite Nanofiber Cartridges | ✔ | |

| Dust Drawer/Tray Bottom Material Outlet | ✔ | |

| Control Box w/ Solid State Timer Board in NEMA 12 Enclosure and Pressure Gauge | ✔ | |

| Quick Lock, Easy-Access Filter Door | ✔ | |

| Unique ACTion Inlet With Spark Arresting Technology | ✔ |

| Paint System | STD | OPT |

| Primed and Painted Interior | ✔ | |

| Multi-Coat Paint Finish | ✔ | |

| Custom Color | ✔ |

| Warranty | STD | OPT |

| 10-Year Warranty | ✔ |

With millions of CFM going through operating ACT Dust Collectors every day worldwide, we have the solution to every application. Custom designed and built systems are common, and our engineering team can help find the dust collection system that's right for you.

| Model | Height (A) | Width (B) | Depth (C) | # of Filters | Filter Area |

| ACTion Booth | 96 | 43 | 47 | 4 | 1400 |

A.C.T. Nano-Elite high efficiency cartridge filters remove 99.9% of the particulate from the air stream. They carry a MERV 15 rating (best in the industry). The cleaned air is then directed to the location of your choice, either returned to the facility or exhausted to the environment.

Phone: 763-557-7162

Toll Free: 800-422-1316

Locations: