A.C.T. Dust Collectors TLM Modular Baghouses are designed to meet the unique requirements of each application. Custom designed and built systems are common, and our engineering team can help find the dust collection system that's right for you.

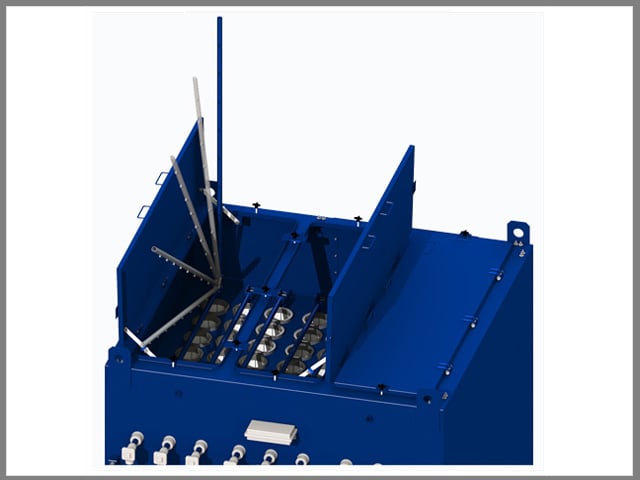

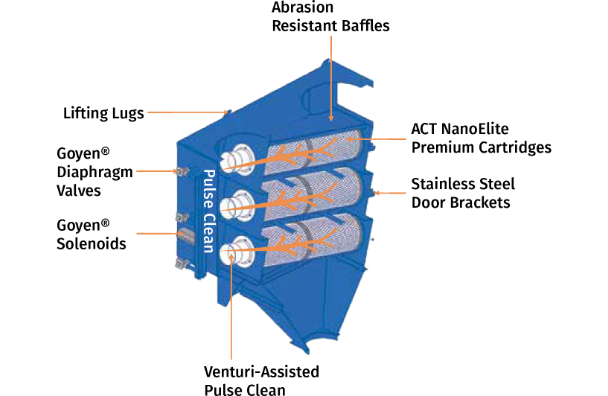

Heavy-duty internally reinforced 10-gauge walls and robust structure meet industry demands. Utilizing computerized simulation software, the pulse-jet cleaning system operational design has been optimized for efficient cleaning and airflow. Hinged filter access doors and our exclusive tool-free bag replacement, allow for the quickest, easiest maintenance.

The TLM Baghouse operation is simple, proven and efficient. Dust-laden air is drawn from the source through a duct system and into the hopper inlet. Through air expansion and an internal deflection plate, the airstream velocity is reduced so large particles drop into the hopper below. The remaining dust particles are filtered through the bag filters. This ensures that only clean air passes into the top of the unit, through the fan, and is either exhausted to the atmosphere or returned to the building.

The TLM Baghouse brings you the culmination of many years of experience with quality and features unrivaled in the industry.

The ACT TLM 279-10 Modular Baghouse is designed to meet the unique requirements of many applications including woodworking, sanding, finishing, food processing, pharmaceutical and other industrial environments.

When it comes to transportation, the dimensions of the TLM Baghouse are such that trucking can be done without oversize permits. Installation is simple and straightforward with the modular design and integral lifting lugs. Overall design is compact to minimize footprint and overall height to fit in the tightest space available.

Utilizing computerized simulation software, the pulse-jet cleaning system operational design has been optimized for efficient cleaning and airflow. Hinged filter access doors and our exclusive tool-free bag replacement, allow for the quickest, easiest maintenance.

When this dust collection system was designed, maintenance was top of mind. Our baghouse dust collectors are easy to maintain because of the following standard features:

Automatic Venturi-Assisted Pulse Filter Cleaning System

ACTion-Lock Exclusive Tool-Free Bag Replacement

Modular Design

OSHA Compliant Hand Rail and Caged Access Ladder

This ACT TLM 279-10 dust collection system holds (279) 10ft long filter bags. The TLM Baghouse features downtime cleaning as well, so the system performs a final pulse-clean cycle after shutdown to ensure maximum dust release and long filter life.

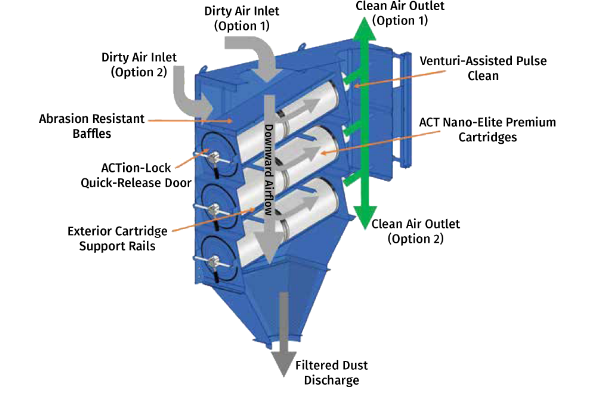

Dirty air from the dust source enters the A.C.T. dust collector at the top of the main housing. There are inlets on the roof and optional inlets on the front for the most efficient connection. As air enters the dust collector, dust accumulates on the outside of the filters as air is drawn through the high-efficiency media. The air flowing down through the system greatly assists the fallout of dust into the hopper where it is discharged. When the pulse clean system activates and accumulated dust is released from the cartridges, the air flowing downward through the collector assists dust fallout again. This avoids dust from getting re-entrained and accumulating on the filter again. Systems with vertical filters — with air entering from the side or below — struggle to avoid dust getting picked back up in the airstream or “re-entrained.”

Your A.C.T. dust collector comes standard with industry-best A.C.T Nano-Elite media. These feature a MERV 15 efficiency rating for effective collection of extremely fine dust, smoke and fume, removing 99.9% of particulate from the air. The cleaned air is then directed to the location of your choice: either returned to your facility or exhausted to the environment.

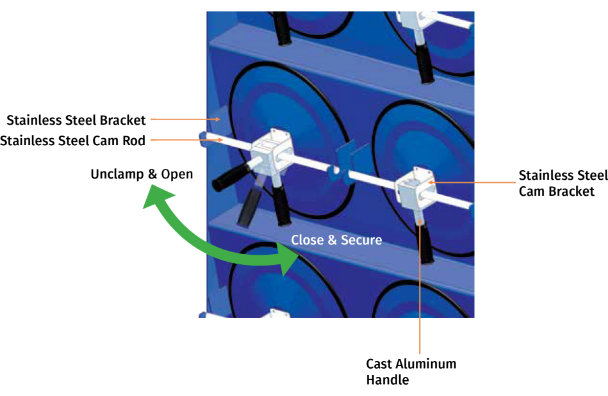

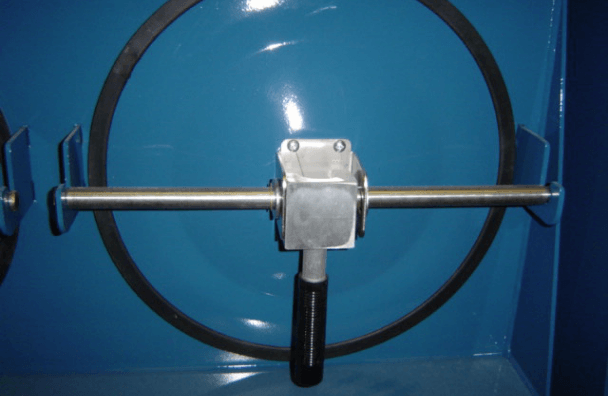

The patented door design of A.C.T. dust collectors is simple, fast and secure. The cast aluminum handle locks the door shut against the dust collector. The heavy-duty cross-rod and brackets on the dust collector and cam are all stainless steel. Knobs, hinges, springs, threads and wasted time are eliminated. Lift the handle and door comes off. Set the cross-rod in the brackets, lower the handle and it’s locked securely. Click Here to watch the video.

Inside the A.C.T. dust collector, the design continues to work. Two rails support the cartridge filters from the front to the back of the housing, eliminating the need for interior yoke support frame cantilevered from the collector tube sheet. The pulse clean system is unobstructed inside the filter for maximum effectiveness.

The most popular feature of the TLM Baghouse series is our Action-Lock Tool-Free Bag Replacement. Top load filter change outs made easy with a hinged filter access door.

Click Here to watch the video.

The main housing of your A.C.T. dust collector is 7 and 10 gauge, all-welded steel. Systems with bolted panel construction can leak over time, so the housing of the A.C.T dust collector is fabricated with continuous, welded seams. Behind every row of two filters is a venturi for maximum performance on the pulse cleaning.

The main housing of the A.C.T. Dust Collector is 7 and 10 gauge, all-welded steel. Systems with bolted panel construction can leak over time, so the housing of the A.C.T Dust Collector is fabricated with continuous, welded seams.

At A.C.T. Dust Collectors, we do more than sell dust collectors. We want to be your number one resource for all your dust collection needs. From our helpful glossary of terms to our on-demand webinars and videos – you can find it all right here. Manuals and brochures for all of our models of dust collectors are also accessible in downloadable formats.

With millions of CFM going through operating A.C.T. Dust Collectors every day worldwide, we have the solution to every application. Custom designed and built systems are common, and our engineering team can help find the dust collection system that's right for you.

| TLM Modular Baghouse | STD | OPT |

| Modular Design | ✔ | |

| Venturi-Assisted Pulse Jet Cleaning | ✔ | |

| Automatic Pulse Controls for both Online & DownTime Cleaning | ✔ | |

| Exclusive Tool-Free Bag Replacement | ✔ | |

| Clean Side, Top Access Snap Band Filter Bags | ✔ | |

| Top Load Filter Change Out | ✔ | |

| Hinged Filter Access Doors | ✔ | |

| No Confined Space Filter Access | ✔ | |

| OSHA Compliant Hand Rail & Cages Access Ladder | ✔ | |

| Replaceable Bolt-On Deflection Baffle | ✔ | |

| Pressure/Vacuum Rating ±25” W.C. | ✔ | |

| Premium Prime & Paint Exterior, High Gloss Enamel | ✔ | |

| 16 oz Polyester Filter Bags with Stainless Steel Snapband | ✔ | |

| Rotary Airlocks with Hopper, Mount Transitions | ✔ | |

| Screw Conveyors | ✔ | |

| Extended/Modified Steel Support Structure | ✔ | |

| Custom Filter Media Options | ✔ | |

| Motor/Blower for Specific Performance | ✔ | |

| Inlet or Outlet Dampers | ✔ | |

| Exhaust Silencer | ✔ | |

| Ductwork and Inlet/Outlet Manifolds | ✔ | |

| Afterfilter Plenums for HEPA or ASHRAE | ✔ | |

| NFPA 69 Compliant Backdraft Dampers / Explosion Isolation Valves | ✔ | |

| Explosion Venting | ✔ | |

| Motor Control Panels (Soft Start, VFD’s, etc.) | ✔ | |

| Spark Detection System | ✔ | |

| High Speed Abort Gates | ✔ | |

| High Temperature Operation Components | ✔ | |

| Stainless Steel Construction | ✔ | |

| Custom Color Exterior, Paint Finishes | ✔ |

With millions of CFM going through operating A.C.T. Dust Collectors every day worldwide, we have the solution to every application. Custom designed and built systems are common, and our engineering team can help find the dust collection system that's right for you.

| Model | Nominal Airflow Range (CFM) | Filter Media (ft2) |

# of TLM 81 Modules |

# of TLM 117 Modules | # of Bags | # of Valves | Bag Length (ft) | Bag Diameter (in) |

Estimated Shipping Weight (lbs) |

Dimensions

A

B

|

|

| TLM 81-10 | 5,000 - 12,000 | 1,272 | 1 | 0 | 81 | 9 | 10 | 6 | 6,000 | 297.21 | 85.02 |

| TLM 117-10 | 7,000 - 18,000 | 1,838 | 0 | 1 | 117 | 13 | 10 | 6 | 7,100 | 321.96 | 117.02 |

| TLM 162-10 | 10,000 - 25,000 | 2,545 | 2 | 0 | 162 | 18 | 10 | 6 | 10,100 | 297.21 | 165.38 |

| TLM 198-10 | 12,000 - 31,000 | 3,110 | 1 | 1 | 198 | 22 | 10 | 6 | 11,200 | 321.96 | 197.38 |

| TLM 234-10 | 14,000 - 36,000 | 3,676 | 0 | 2 | 234 | 26 | 10 | 6 | 12,400 | 321.96 | 229.38 |

| TLM 279-10 | 17,000 - 43,000 | 4,383 | 2 | 1 | 279 | 31 | 10 | 6 | 15,500 | 321.96 | 277.74 |

| TLM 315-10 | 19,000 - 50,000 | 4,948 | 1 | 2 | 315 | 35 | 10 | 6 | 16,600 | 321.96 | 309.74 |

| TLM 351-10 | 22,000 - 55,000 | 5,513 | 0 | 3 | 351 | 39 | 10 | 6 | 17,700 | 321.96 | 341.74 |

| TLM 396-10 | 24,000 - 62,000 | 6,220 | 2 | 2 | 396 | 44 | 10 | 6 | 20,700 | 321.96 | 390.09 |

| TLM 432-10 | 27,000 - 67,000 | 6,786 | 1 | 3 | 432 | 48 | 10 | 6 | 21,800 | 321.96 | 422.09 |

| TLM 468-10 | 29,000 - 73,000 | 7,351 | 0 | 4 | 468 | 52 | 10 | 6 | 23,000 | 321.96 | 454.09 |

| TLM 513-10 | 32,000 - 80,000 | 8,058 | 2 | 3 | 513 | 57 | 10 | 6 | 26,100 | 321.96 | 502.45 |

| TLM 549-10 | 34,000 - 86,000 | 8,624 | 1 | 4 | 549 | 61 | 10 | 6 | 27,200 | 321.96 | 534.45 |

| TLM 585-10 | 36,000 - 91,000 | 9,189 | 0 | 5 | 585 | 65 | 10 | 6 | 28,300 | 321.96 | 566.45 |

| TLM 630-10 | 39,000 - 98,000 | 9,896 | 2 | 4 | 630 | 70 | 10 | 6 | 31,200 | 321.96 | 614.81 |

| TLM 666-10 | 41,000 - 104,000 | 10,462 | 1 | 5 | 666 | 74 | 10 | 6 | 32,300 | 321.96 | 646.81 |

| TLM 702-10 | 44,000 - 110,000 | 11,027 | 0 | 6 | 702 | 78 | 10 | 6 | 33,500 | 321.96 | 678.81 |

| TLM 756-10 | 47,000 - 118,000 | 11,875 | 5 | 3 | 756 | 84 | 10 | 6 | 38,500 | 321.96 | 743.53 |

| TLM 792-10 | 49,000 - 124,000 | 12,441 | 4 | 4 | 792 | 88 | 10 | 6 | 39,700 | 321.96 | 775.53 |

Phone: 763-557-7162

Toll Free: 800-422-1316

Locations: