If you have the right industrial dust collector for your application, keeping it maintained typically requires a small amount of time and money. However, a dust collector does require the regular maintenance and upkeep.

If you have the right industrial dust collector for your application, keeping it maintained typically requires a small amount of time and money. However, a dust collector does require the regular maintenance and upkeep.

Performing regular dust collector maintenance keeps your system working properly. After all, you lose money in repairs and system downtime when something goes wrong.

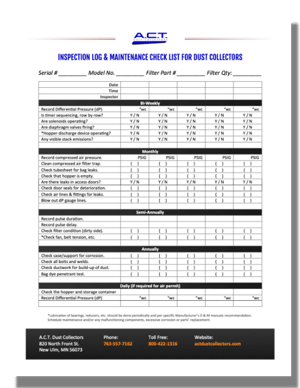

At A.C.T. Dust Collectors, we recommend bi-weekly, monthly, semi-annual and annual maintenance to the dust collector to keep the system running at its best. In some situations where an air permit is required, there are some daily checks that have to be completed, such as checking the hopper and recording differential pressure (dP).

Simple cleaning and maintenance tasks not only improve the performance of your industrial dust collector but can extend the life of it as well.

Use this dust collector maintenance checklist to keep your system working properly.

Industrial Dust Collector Maintenance Schedule

Bi-Weekly Dust Collector Maintenance

The differential pressure should be recorded during every bi-weekly dust collector maintenance check. This will help you to make sure that the filters are replaced before they get clogged.

Filters are key to the performance of a dust collection system. Using the wrong filter type results in an inefficient dust collector. It’s important to know the different methods used to clean filters and when the filters should be replaced.

To make sure your dust collector is operating smoothly, ask yourself the following questions:

- Is the timer sequencing, row by row?

- Are solenoids operating?

- Are diaphragm valves firing?

- Hopper discharge device operating?

- Any visible stack emissions?

If the answer to any of these questions causes concern, you likely need to perform further maintenance.

Monthly Dust Collector Maintenance

The monthly dust collector maintenance checklist has the most items to go through. However, they’re all quick and easy.

- Record compressed air pressure

- Clean compressed air filter trap

- Check tube sheet for bag leaks

- Check that hopper is empty

- Check access doors for leaks

- Check door seals for deterioration

- Check air lines and fittings for leaks

- Blow out differential pressure gauge lines

If any of these checks cause concern, you likely need to perform further maintenance.

Semi-Annual Dust Collector Maintenance

Every six months, the pulse duration and pulse delay should be recorded. This can be compared to the data collected six months before to ensure that the performance of the system has not changed. This is also the time to check your filters. Some systems in certain applications or where multiple shifts are run may require filter changes in as short as six-month periods.

The blower should be inspected semi-annually to ensure it is performing correctly. Lubrication may also be required.

Annual Dust Collector Maintenance

Annual dust collector maintenance checks are more for general wear and tear, such as the bolts, welds and corrosion on the support steel. The ductwork also needs to be checked for dust buildup.

Some baghouse dust collectors require a dye test to make sure that dust is not leaking out of the system where it shouldn’t be.

Improve the Performance & Extend the Life of Your Dust Collector

Dust collector maintenance is essential to long-term performance. Downtime to perform maintenance or switch out a part equates to labor cost, so consider equipment that is of high quality that won’t need excessive maintenance beyond the typical filter change-outs and cleaning operations.

By reducing the frequency of part replacement, you reduce the amount being disposed of and the associated costs of disposal. This is another reason why part quality and long service life are paramount to cost saving. This should also be considered when buying the dust collector. Lower air-to-cloth ratios will result in better filter life, lower electrical consumption and fewer disposal costs.

If you have any questions about the maintenance of your industrial dust collection system, reach out to the A.C.T. team. We would be happy to help make sure your system is running its best, or provide alternative dust collecting options.

%20Collectors%20Image.png?width=143&height=143&name=ADC%20(Ambient)%20Collectors%20Image.png)

.png?width=240&height=91&name=ACT%20Dust%20Collectors%20Logo%20Solid%20White%202020%20(1).png)

.png?width=148&height=149&name=usa-manufactured-dust-collectors%20(1).png)