Industrial dust collectors are essential for maintaining a safe and healthy work environment in many industries. They capture and remove harmful dust particles from the air, preventing them from being inhaled by workers or settling on surfaces. However, for dust collectors to function effectively, their filters need to be properly maintained.

Industrial dust collectors are essential for maintaining a safe and healthy work environment in many industries. They capture and remove harmful dust particles from the air, preventing them from being inhaled by workers or settling on surfaces. However, for dust collectors to function effectively, their filters need to be properly maintained.

Importance of Filter Maintenance

Neglecting dust collector filter maintenance can lead to several problems:- Reduced airflow: Clogged filters restrict airflow, making the dust collector less efficient at capturing dust.

- Increased energy consumption: The dust collector has to work harder to overcome the airflow restriction, leading to higher energy costs.

- Premature filter failure: Clogged filters are more likely to tear or rupture, requiring more frequent replacements.

- Health and safety hazards: Leaking filters can release dust particles back into the air, posing a health risk to workers.

Filter Maintenance Tips

To prevent these problems, it's crucial to follow a maintenance schedule for your industrial dust collector filters. Here are some key tips:

Inspection

Filters should be inspected only when bypass or big changes in pressure differential are discovered. The differential pressure readout is the best way to monitor the condition of your filter. Any signs of dust bypass (either high pressure or a sudden drop in differential pressure) are signs the filters should be inspected. Shine a flashlight to search for tears or pinholes that might let dust leak through. Check for rips, abrasions, or uneven color variations, which could indicate weakened fabric or filter damage. Remember, gloves and a dust mask are your allies in this dusty battlefield.

Cleaning

There are typically three different types of filter cleaning systems, including:

- Shaker systems

- Pulse jet systems

- Reverse flow systems

Shaker systems and pulse jet systems are used in cartridge or baghouse dust collectors. A shaker system is generally used for an intermittent use dust collector whereas a pulse jet system is used for a production dust collector. Reverse flow systems are used in baghouse dust collectors only.

Many dust collectors have an automatic pulse cleaning system that will clean the filters with compressed air. The filters must be cleaned with dry and clean air. Some dust collectors, such as A.C.T. Dust Collectors, have a down-time clean feature that will automatically clean the filters at the end of every shift. In addition to this, they have online cleaning capabilities based on pressure differential or continuous cleaning.

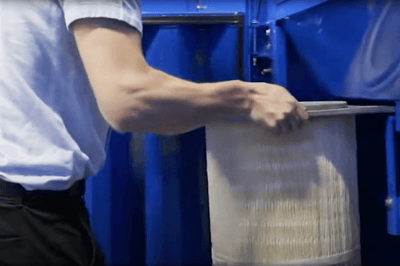

Replacement

Replace dust collector filters promptly when they are damaged or no longer effective. The frequency of filter replacement will vary depending on the type of dust collector and the dust load. Decreased airflow or ineffective dust capture are red flags. Visible damage or age-related wear and tear naturally call for replacement. Remember, heavy dust environments, abrasive particles, high humidity, and frequent cleaning can shorten a filter's lifespan. Keep some spare filters handy to avoid downtime during peak production periods.

Recordkeeping

Keep track of inspection, cleaning, and replacement dates to ensure that you are adhering to a regular maintenance schedule. This can help you identify trends, predict future maintenance needs, and optimize cleaning and replacement schedules.

Additional Maintenance Considerations

In addition to the above tips, there are a few other things to keep in mind when maintaining industrial dust collector filters:

- Use the right filters: Make sure you are using the correct type of filters for your dust collector and the specific dust particles you are trying to capture.

- Follow the manufacturer's instructions: Each dust collector and filter is different, so be sure to follow the manufacturer's specific instructions for maintenance.

- Seek professional guidance: If you are unsure about how to maintain your dust collector filters, consult with a qualified technician.

By following these tips, you can ensure that your industrial dust collector filters are functioning properly and effectively protecting your workers and your work environment.

Extend the Life of Your Industrial Dust Collector Filters

Industrial dust collector filters play a vital role in maintaining a safe and healthy work environment. By following a regular maintenance schedule, you can extend the life of your filters, improve the efficiency of your dust collector, and protect your workers from harmful dust particles.

For more information on industrial dust collector filters and maintenance, contact us today.

%20Collectors%20Image.png?width=143&height=143&name=ADC%20(Ambient)%20Collectors%20Image.png)

.png?width=240&height=91&name=ACT%20Dust%20Collectors%20Logo%20Solid%20White%202020%20(1).png)

.png?width=148&height=149&name=usa-manufactured-dust-collectors%20(1).png)