A reverse pulse (often called a pulse jet or reverse jet) filter cleaning system is a simple action that has significant results. A simple explanation of a reverse pulse filter cleaning system is as follows: in normal dust collector operation, air flows from the outside of the filter media to the center of the filter. The dust is filtered out and left on the outside surface of the filter.

A reverse pulse (often called a pulse jet or reverse jet) filter cleaning system is a simple action that has significant results. A simple explanation of a reverse pulse filter cleaning system is as follows: in normal dust collector operation, air flows from the outside of the filter media to the center of the filter. The dust is filtered out and left on the outside surface of the filter.

To clean off this dust, a blast of compressed air is shot down the center of the filter and works outward taking the dust off of the surface of the filter. In a downflow dust collector, such as an A.C.T. dust collector, the dust is captured by that downward airflow and eventually deposited in the collection bin.

PULSE CLEAN SYSTEM SETUP

compressed air conNection:

The compressed air connection can be plumbed in using heavy duty, industrial rubber tubing or black pipe. It is important to ensure that you have an inline air regulator installed which can maintain your desired PSI level. If your air compressor is inside and the air travels to your dust collector, keep in mind the drop in temperature through the line can cause condensation. Condensation can directly effect the performance of your collector. Winterize Your Facility and Outdoor Industrial Dust Collector to Improve Indoor Air Quality.

PSI REQUIREMENTS:

Pulse clean should operate at 90 PSI. PSI stands for pounds per square inch; a unit of pressure; 1 PSI equals 27.7 in. WG or 2.04 in. mercury (Hg); can be actual or gauge pressure. In the metric system, this is measured as kg/cm2 . (The conversion is kg/cm2 x 14.22 = PSI.) Turning up the pressure of your compressed air does not mean you will get a better pulse. Too much pressure can damage your filters and diaphragms which can cause bypass. For best results, we recommend using dry compressed air.

other items to consider:

- A filter cleaning system does not mean that you never have to change your filters; it will significantly extend your filter life, but filters will still need to be changed. Shop OEM replacement filters online.

- A solenoid heater kit is directly linked to the pulse cleaning system and the compressed air line. Read our Blog: Why is a Solenoid Heater Kit Important?

- The electrical requirements for the solenoids.

- The importance of avoiding moisture in your diaphragms especially in colder climates as it can freeze and crack the diaphragm.

opperating principles

An inefficient pulse cleaning system on a dust collector can lead to unnecessary downtime, excess energy consumption, and ineffective dust filtration. A properly working pulse cleaning system will pulse compressed air automatically cleaning your filters. The short-duration pulse of compressed air helps to dislodge the fine particles of dust attached to the filters. Without an effective cleaning system, dust particulate will continue to build on the filter media. Learn more about timer boards with this helpful video.

Two Types of cleaning:

1. Online cleaning while the fan is running as related to the high and low limit

The high limit on your differential pressure gauge sets the point at which the pulse cleaning begins. Your high limit differential pressure number is set based on the application. Once that high limit is determined, we recommend setting your low limit within one inch of the static pressure variance.

2. Downtime cleaning: fan is shut off completely

This can be controlled and scheduled through the control panel/timer board to control the duration of cleaning. Downtime cleaning is determined by the daily usage of your dust collector; a typical range would be a 5-10 minute cycle. It is the most effective time to clean your filters so you are ready for your next start-up. The downtime cycle will automatically begin once the stop button is pressed on the unit and will automatically end at the predetermined time.

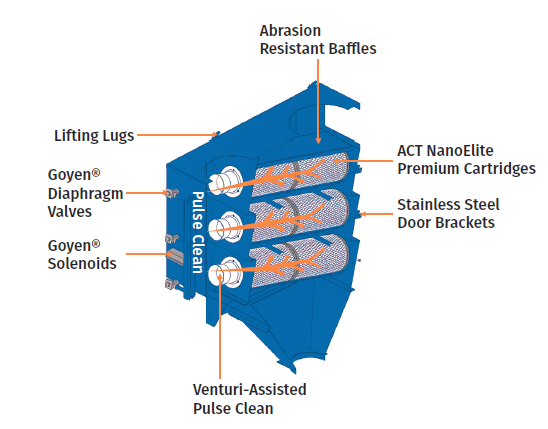

INSIDE THE A.C.T. Dust Collector

When the A.C.T. dust collection units were designed, maintenance was top of mind. Two rails support the cartridge filters from the front to the back of the housing, eliminating the need for an interior yoke support frame. Our unique design allows the pulse cleaning system to work with zero obstruction inside the filter for maximum effectiveness. Our cartridge dust collectors are easy to maintain due to the following standard features:

- Support Rails

- An Automatic Venturi-Assisted Pulse Filter Cleaning System

- The ACTion-Lock Quick Release Filter Doors

- Ease of Access to Filters

Download the Inspection Log & Dust Collector Maintenance Checklist. For more information on our industrial dust collectors, or to discuss your specific needs, please contact us.

%20Collectors%20Image.png?width=143&height=143&name=ADC%20(Ambient)%20Collectors%20Image.png)

.png?width=240&height=91&name=ACT%20Dust%20Collectors%20Logo%20Solid%20White%202020%20(1).png)

.png?width=148&height=149&name=usa-manufactured-dust-collectors%20(1).png)