A customer in Texas purchased a new fiber laser cutting machine. The machine offers incredible precision and speed but produces an extremely fine dust during operation. The company reached out to A.C.T. Dust Collectors to find a solution to their fiber laser dust collection.

Dust collectors for fiber laser cutting machines

Laser and plasma cutting creates a major source of fume, smoke, dust and various oxides. Therefore, it’s important to have a laser fume extractor on site for the safety of personnel and proper operation of expensive equipment. Laser cutting utilizes a focused beam of light and is recommended for applications where parts require tighter tolerances. Plasma cutting, which uses a mixture of gases to cut, is a popular process for cutting stainless steel and is widely used in the manufacturing industry.

The Board of Laser Safety explained how, during the cutting process, high temperatures cause the surrounding air to expand. Once materials are being treated by the laser beam, they'll emit gases that rapidly expand and release dangerous particles. Thus laser cutting processes can produce very find dust particles that can be harmful to workers and the equipment.

Laser cutting Dust solution found

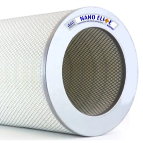

Our team has extensive experience with fiber laser cutting applications. One important factor with this type of application is the filter media. To collect the very fine dust that this machine produces, you have to ensure that the dust collector has the correct filter media.

Nanofiber filters effectively collect particles in the 0.3 to 0.7 micron range (fine dust). A.C.T Dust Collectors NanoElite is a premium Nanofiber filter and comes standard across the whole range of dust collectors. This type of filter keeps the particulate collected on the surface of the media and prevents it from embedding (called blinding) in the filter, known as surface loading. Surface loading allows the dust to be removed with ease when the filters are pulse-cleaned, which results in longer filter life. While other specialty media filters are available, the A.C.T. NanoElite filters were ideal for this application.

After research was conducted on the capacity required to effectively capture the dust, it was agreed that the A.C.T. LaserPack 6 was the best option for this application. It is designed for use in fiber laser applications.

The LaserPack 6 came equipped with:

- Integrated spark trap

- Pre-wired controls

- Noise attenuation blower enclosure

- Remote start feature (This made it so the dust collector can be controlled from the fiber laser machine.)

The Texas customer experienced the value of pre-packaged solution offered by the A.C.T. LaserPack 6 with the NanoElite cartridge filters. For extra insurance, we added a HEPA after filter plenum for additional protection from super fine dust.

After 6 months, the customer reached out and told us that they are impressed with the unit. “It’s working great!” the plant manager reported. They have not had to replace cartridge filters and are pleased with how the system is running.

A.C.T. Dust Collectors are installed all over North America in many applications. Our team has the knowledge and skills required to help you resolve the dust problem at your facility the most quick and efficient way.

Contact the industrial dust collector manufacturers at A.C.T. Dust Collectors or request a quote today!

%20Collectors%20Image.png?width=143&height=143&name=ADC%20(Ambient)%20Collectors%20Image.png)